Horizontal Flow Wrapper (Standard Model)

PSA-250NS (Non-Shrinkable Model), PSA-250WS (Shrinkable Model)

Flow wrapper, Flow wrapping machine, Horizontal Flow Wrap Machine, Flow Wrap Machine

The Standard Horizontal Flow Wrapper is a customized machine designed for medium- to high-speed production lines that demand a premium packaging appearance. Equipped with a high-performance servo control system and a tailor-made forming device, it ensures every product is sealed with consistent accuracy and a professional finish.

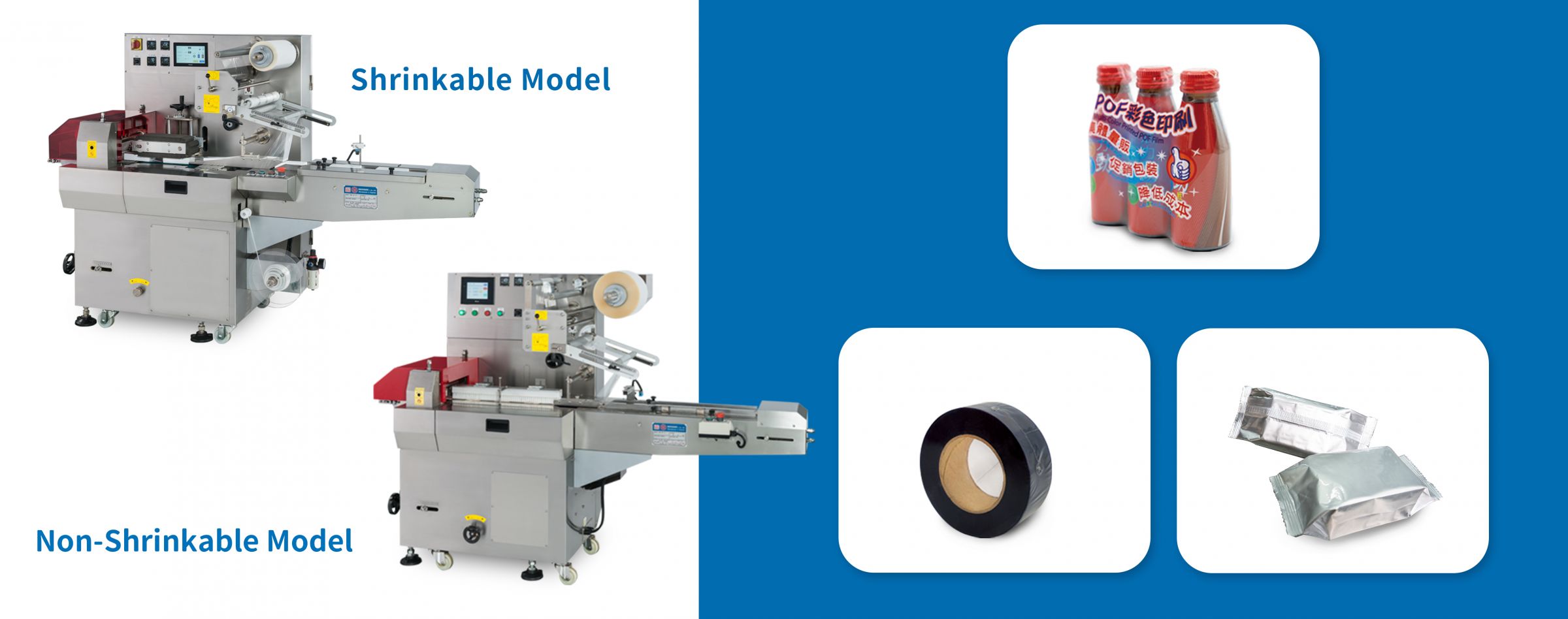

This series comes in two models:

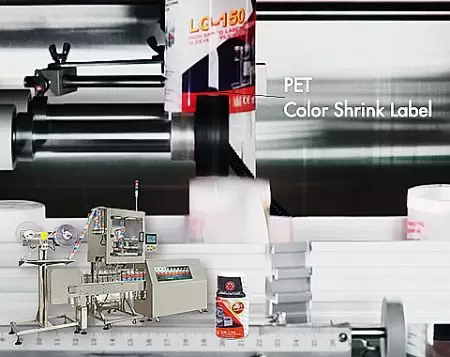

- PSA-250N (Non-Shrink Type) – Compatible with standard flexible films such as BOPP, CPP, laminated films, and aluminum rolls. Commonly used for packaging baked goods, cookies, and disposable products.

- PSA-250W (Shrink Type) – Designed for POF shrink film and requires a shrink tunnel for operation. This option delivers tighter, more attractive packaging, ideal for products such as food, cosmetics, and other consumer goods that benefit from a premium look.

Whether for food, daily necessities, medical supplies, or electronic components, the PSA-250 series provides a High-efficiency, stable, and reliable automated packaging solution.

Are you unsure which packaging material is best for your product? Simply fill out the inquiry form below, and our team will provide you with a one-stop packaging solution consultation—covering everything from film materials and packaging equipment to full production line planning.

Features

- High Speed & Productivity: Capable of reaching up to 80 packs per minute, making it ideal for production lines that require consistent and stable output.

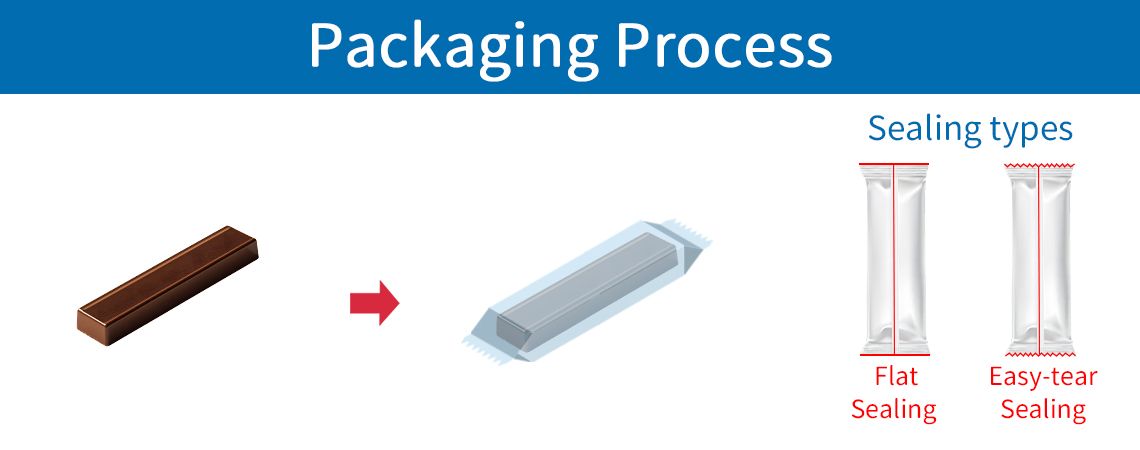

- Accurate Forming & Sealing: Equipped with a customized forming device and a stable push-rod feeding system to prevent inconsistent bag lengths or loose packaging. The I-type sealing design delivers a smooth, clean finish that enhances product presentation.

- Energy-Saving & Eco-Friendly: Reduces film waste and lowers long-term operating costs. Combined with an advanced servo control system, the machine ensures lower energy consumption.

- Durable & Easy to Maintain: Designed for simple maintenance and longer service life, reducing downtime and maximizing machine reliability.

- Flexible Integration: It can be easily connected with printers, labelers, card inserters, or automatic feeding systems. Highly adaptable for future production upgrades.

- Professional Appearance: Works with both non-shrink films for clear product visibility and POF shrink film for a tight, glossy finish—enhancing shelf appeal and overall brand image.

Specification

Machine Dimension: 4720 (L) x 850 (W) x 1650 H) (m/m)

Power Requirement: 3.5KW 220V 1ph

Packaging Speed: 80 (pack/min)

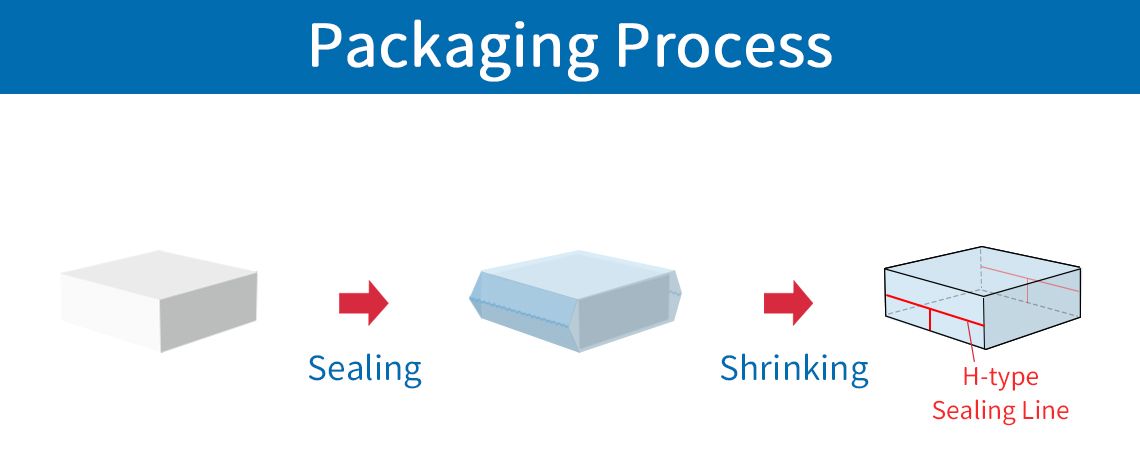

Sealing Type: H-Type

Weight: 1000kg

Horse Power: 2HP x 1

Heat: 400W x 2 / 300W x 4

Frame: SUS Main Body.

Film Feeding Roller: 500mm auto centralization device.

Special Features: Sealing Safe System, Wasting Trim Winding Unit, Former X1, Film Tension Control System, No Film No Work Mechanism, Stop Work for No Product Feeding & HMI Control System, Mercury electric condition for TD sealer, Optional accessories can be designed by exact working requirement.

Applications

- Food & Beverages: sauce bottles, seasoning jars, coffee cans, carbonated drinks, juices, mineral water, tea beverages, sports drinks, dairy products, yogurt, and energy drinks.

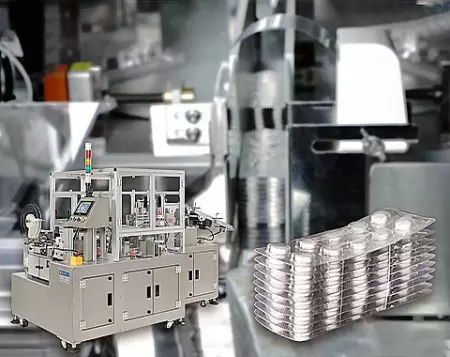

- Health & Pharmaceuticals: vitamins, capsules, pharmaceutical containers, functional drinks, and medical-grade disinfectants.

- Beauty & Personal Care: Used for shampoo, body wash, conditioner, lotions, cosmetics, perfume bottles, and nail polish.

- Household & Cleaning Products: dishwashing liquid, cleaning agents, disinfectant sprays, air fresheners, and insect repellents.

- Industrial & Chemical Products: engine oil, lubricants, industrial cleaners, paints and coatings, and pesticide containers.

- Movies

- Related Products

- Files Download

Recommendation of popular products, please see the product introducing pages for more details.

Horizontal Flow Wrapper (Standard Model) | Innovative Heat Shrink Machines and Sustainable Packaging Films

Established in 1962 and based in Taiwan, Benison & Co., Ltd. is a leading supplier of packaging solutions. We specialize in Horizontal Flow Wrapper (Standard Model), shrink packaging, heat shrink films, tamper-evident bands, and automated packaging machines for the food, beverage, pharmaceutical, and industrial sectors. Our products include horizontal flow wrappers, auto label sleeve applicators, and over-wrapping machines, all designed to enhance production efficiency and reliability.

Our expertise spans both packaging machinery and film production, offering industry-leading technology and eco-friendly solutions. Advanced heat shrink packaging machines and automatic shrink wrap systems ensure high efficiency and reliability for various industrial applications. Sustainable shrink films provide excellent product protection and presentation. Focused on innovation and comprehensive customer service, we attract international buyers seeking top-quality and reliable packaging solutions, reinforcing our position as a global leader in the packaging industry.

Benison has been offering customers high-quality heat shrink packaging and shrink wrap machines, both with advanced technology and 60 years of experience, Benison ensures each customer's demands are met.