Ear Thermometer Probe Covers

In medical institutions, the manual counting and packaging of ear thermometer probe covers often lead to errors, affecting both efficiency and product quality. To enhance productivity and ensure compliance with medical standards, we customized a fully automated ear cover cartoning and packaging system for a hospital, successfully resolving their key challenges.

▍Challenges and Requirements

◆ Manual counting errors:The hospital reported that manual counting of probe covers was not only time-consuming but also prone to inaccuracies, significantly increasing packaging costs.

◆ Need for automated printing and labeling:The current packaging process lacked automated date printing and labeling functions. Manual handling was inefficient and made it difficult to maintain timely and accurate product information.

◆ Limited factory space:The hospital's facility had limited space, requiring an automated packaging line designed to fit within existing spatial constraints.

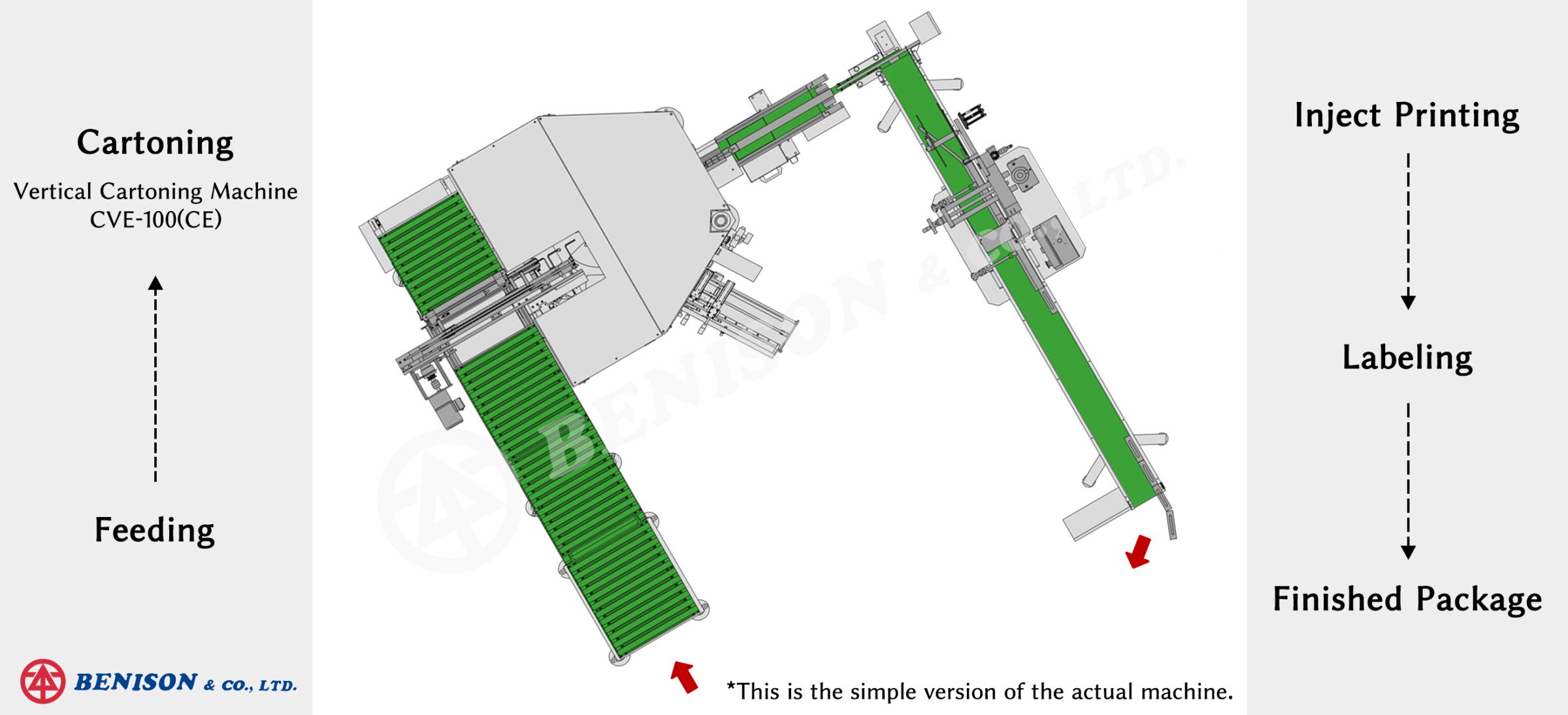

After an in-depth consultation, the Benison team recommended the Vertical Cartoning Machine, CVE-100(CE) and customized the system design according to the client's requirements and space limitations, which included:

◆ Feeding Tray Design

◆ Integration of Auto Inkjet Printing and Labeling Devices

◆ Turning Pusher Design

▍Production Line Design and Planning

Feeding Tray Design

During discussions, the hospital noted that manual counting was both error-prone and time-consuming. To address this, we designed a customized tray and collective feeding system that allows automatic counting and smooth feeding of probe covers into the cartoner—eliminating the need for manual verification.

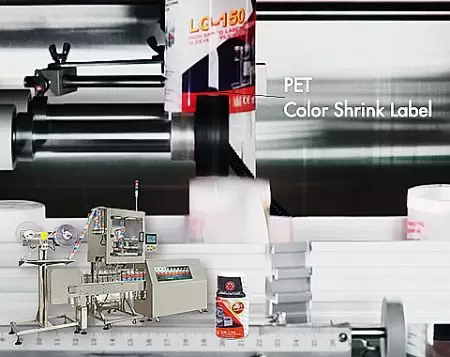

Integration of Auto Inkjet Printing and Labeling Devices

Product traceability is essential in medical consumable packaging. The hospital requested automated printing and labeling capabilities. After evaluating actual workflow and factory layout, Benison proposed the most suitable configuration and integrated the inkjet printer and labeling machine into the line. This setup enables each package to be automatically printed with date codes and labeled efficiently.

Custom Production Line Solutions:Improving Accuracy and Reducing Labor Costs

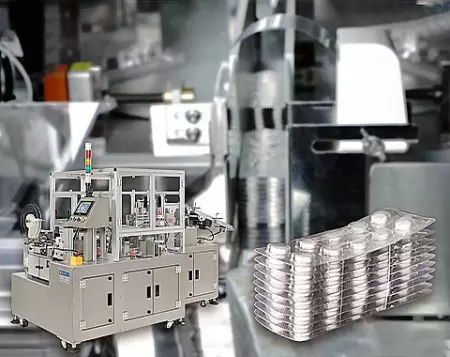

◆ Automatic Cartoning Machine:Delivers high performance and stability, suitable for medical product packaging applications.

◆ Automated Integrated Line:Combines tray feeding, inkjet printing, labeling, and turning pusher to achieve a fully automated packaging process.

◆ Compliant with Medical Standards:The entire process adheres to medical industry regulations, ensuring product quality and safety.

After implementing the automated packaging line, the hospital achieved a significant increase in production efficiency, a notable reduction in human errors, and improved traceability and compliance for all packaged products.

▍Machine Features & Specifications

Vertical Cartoning Machine, CVE-100(CE)

- Customized feeding system designed for collective cartoning, enabling easy and efficient product loading.

- Unique hexagonal frame improves machine flexibility in a production line.

- Compact size machine with turntable design could save working space.

- The stainless steel frame and anti-rust parts of the whole machine meet the needs of various industries.

- Applicable box type: Flat tap, gluing seal & one-touch

- Can be made to fit auto feeding or semi-auto feeding system.

- Recommended to industries of food, such honey can, pharmaceutical, such as eye drop bottle & any other products, which must be fed by vertical position.

- The equipment, material and quantity can be adjusted based on actual production needs.

- Benison can provide consultation about plant layout planning, production line optimization, and labor allocation.

| Packaging Capacity | 60 packs/minute (depends on product size) |

| Output | Collective Cartoning Packaging |

How To Get A Solution Proposal?

Any problems or questions are welcome. Do not hesitate to contact us by enquiry form below or our hotline service. Benison professional consultant team will evaluate your existing plan and expected output product. In addition, Benison team will arrange further contacts in order to understand your needs.

- Gallery

- Related Products

- Files Download

Recommendation of popular products, please see the product introducing pages for more details.

Ear Thermometer Probe Covers | Global Leader in High-Efficiency Packaging Machines and Materials

Established in 1962 and based in Taiwan, Benison & Co., Ltd. is a leading supplier of packaging solutions. We specialize in shrink packaging, heat shrink films, tamper-evident bands, and automated packaging machines for the food, beverage, pharmaceutical, and industrial sectors. Our products include horizontal flow wrappers, auto label sleeve applicators, and over-wrapping machines, all designed to enhance production efficiency and reliability.

Our expertise spans both packaging machinery and film production, offering industry-leading technology and eco-friendly solutions. Advanced heat shrink packaging machines and automatic shrink wrap systems ensure high efficiency and reliability for various industrial applications. Sustainable shrink films provide excellent product protection and presentation. Focused on innovation and comprehensive customer service, we attract international buyers seeking top-quality and reliable packaging solutions, reinforcing our position as a global leader in the packaging industry.

Benison has been offering customers high-quality heat shrink packaging and shrink wrap machines, both with advanced technology and 60 years of experience, Benison ensures each customer's demands are met.