Eye Drop Collective Packaging

A medical product manufacturer approached us with a practical question: " We need to pack three blister eye drop units into one carton, with an instruction leaflet included. Right now, manual packing takes too much time. Is there a better way to do this? "

This situation is common in the medical and healthcare industry. When operators have to count units, insert leaflets, and load cartons by hand, the process is not only labor-intensive but also prone to errors.

So how can this type of collective cartoning be handled more efficiently?

▍Challenges and Requirements

◆ Time-consuming manual packing:Operators must repeatedly count blister units, insert leaflets, and load cartons. Manual efficiency can no longer keep up with increasing order volumes.

◆ High error rates:Manual operations often lead to incorrect unit counts or missing instruction leaflets.

◆ Limited factory space:The available floor space is restricted, so equipment layout must remain compact. Conveyor directions also need to match existing production flow to keep the line running smoothly.

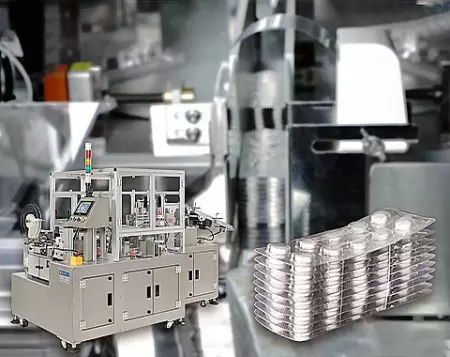

After understanding the customer' s production pace and space limitations, Benison proposed an automated solution built around theIntermittent Horizontal Cartoning Machine, CHS-120 (CE).

Based on actual production needs, the system was integrated with three key functions:

◆ Photoelectric Sensor and rejection system

◆ Counting and stacking Design

◆ Instruction Leaflet Feeding Design

▍Production Line Design and Planning

Photoelectric Sensor and rejection system

During the discussion, the customer mentioned frequent issues with incorrect quantities and missing leaflets. To address this, multiple photo-eye detection points were added to monitor carton presence, product spacing, and leaflet insertion status in real time. Any abnormal cartons are automatically rejected. This design significantly improves line stability while reducing defect rates and overall production cost.

Counting and stacking Design

The customer wanted three blister eye drop units packed as one set—without increasing line complexity. A counting and stacking module was integrated directly into the horizontal cartoner, allowing grouping and cartoning to be completed on a single machine. Operators can adjust parameters via the control panel to switch settings easily. The process remains smooth and compact, without requiring additional floor space.

Customized Machine Design:Flexible Integration for Different Packaging Needs

◆ Customized Configuration:One machine handles counting, leaflet insertion, and cartoning.

◆ Space-efficient Layout Planning:Cartoning is completed within a limited footprint, with conveyor layouts adjusted to match factory constraints.

◆ Reduced Defect Rates:Multiple photoelectric sensors stabilize the process and minimize rejects.

▍Machine Features & Specifications

Intermittent Horizontal Cartoning Machine, CHS-120(CE)

- Combines counting, cartoning, and leaflet insertion in one system

- High flexibility for factory space utilization

- Three-axis servo control system

- Stainless steel construction for easy cleaning and corrosion resistance

- Applicable box type: Flat tap, gluing seal & one-touch

- Multiple rejection points to minimize defective output

- Customizable design based on production requirements

- Suitable for biotech, pharmaceutical, medical, healthcare, and personal care industries

- The equipment, material and quantity can be adjusted based on actual production needs.

- Benison can provide consultation about plant layout planning, production line optimization, and labor allocation.

| Packaging Capacity | 60 packs/minute (depends on product size) |

| Output | Counting and Collective Cartoning Packaging |

How To Get A Solution Proposal?

Any problems or questions are welcome. Do not hesitate to contact us by enquiry form below or our hotline service. Benison professional consultant team will evaluate your existing plan and expected output product. In addition, Benison team will arrange further contacts in order to understand your needs.

- Gallery

- Related Products

- Files Download

Recommendation of popular products, please see the product introducing pages for more details.

Eye Drop Collective Packaging | Global Leader in High-Efficiency Packaging Machines and Materials

Established in 1962 and based in Taiwan, Benison & Co., Ltd. is a leading supplier of packaging solutions. We specialize in shrink packaging, heat shrink films, tamper-evident bands, and automated packaging machines for the food, beverage, pharmaceutical, and industrial sectors. Our products include horizontal flow wrappers, auto label sleeve applicators, and over-wrapping machines, all designed to enhance production efficiency and reliability.

Our expertise spans both packaging machinery and film production, offering industry-leading technology and eco-friendly solutions. Advanced heat shrink packaging machines and automatic shrink wrap systems ensure high efficiency and reliability for various industrial applications. Sustainable shrink films provide excellent product protection and presentation. Focused on innovation and comprehensive customer service, we attract international buyers seeking top-quality and reliable packaging solutions, reinforcing our position as a global leader in the packaging industry.

Benison has been offering customers high-quality heat shrink packaging and shrink wrap machines, both with advanced technology and 60 years of experience, Benison ensures each customer's demands are met.