Packaging Machinery Training: Boosting Sustainability and Efficiency

From the moment a new piece of packaging machinery is introduced, the real challenge for a company is no longer just the purchase itself—it' s how to ensure operators truly master the equipment and bring out its full potential.

Many people assume that being able to start and stop the machine means the training is done. In reality, the connection between operator proficiency and production performance runs far deeper than most expect.

During our work supporting clients with production optimization, we' ve repeatedly observed the same pattern: sustainability and yield issues often don' t come from the machine—it' s the gap between the operator and the equipment.

Beyond Safety—What Should Good Training Include?

Safety is always the basic requirement. But to operate efficiently, training should also cover:

1.A solid understanding of all machine functions, including material changes, maintenance, and troubleshooting.

2.How to manage production rhythm and adjust settings when needed.

3.Knowing the difference between a necessary full stop and a simple parameter tweak. That' s where real efficiency begins.

When your operators are sharp, your packaging line will run smooth, fast, and with rock-solid consistency.

The Cost of Poor Training

Many companies underestimate the impact of insufficient training. The losses can be larger than expected:

1.Increased material waste:Improper film loading or wrong settings can lead to hundreds of meters of scrap in a single day.

2.Higher maintenance expenses:Incorrect operation accelerates wear and may even cause early machine damage.

3.Quality is all over the map:A dip in yield means you're constantly fighting off rework and repackaging jobs.

4.Sudden stops:Just one unexpected halt can throw an entire shipment schedule off track.

And that' s not even counting the potential safety risks or the extra cost and time for remedial training.

Poor Training Affects Sustainability Too

Few people realize that inadequate training also creates a real environmental burden. Incorrect material use and repeated packaging both increase waste.

Some clients ask, “Is there really a big difference between POF and PVC?” Our take is simple: it's not just about the material—it's about the operator knowing how to maximize it. Even the best eco-friendly materials cause waste if they're used incorrectly.

ESG efforts don' t start in reports; they start at every step of the packaging line.

How to Obtain High-Quality Packaging Machinery Training

Before equipment installation, it' s worth confirming whether the training will include:

1.Is the training conducted by professionals with practical experience?

2.Does it cover not only “operation” but also material selection, parameter optimization, and troubleshooting?

3.Does it include hands-on practice that simulates real production conditions?

4.Is technical support and improvement advice available afterward?

When operators truly know what they' re doing, machines run better — and the whole team works with real confidence, not guesswork.

Training Is an Investment, Not an Expense

To us, packaging training is never just an optional service. It' s the foundation that keeps production stable. When operators are trained well, machines perform better, and the team works with greater confidence.

Thinking about that next big line upgrade? Or maybe bringing in new kit? Our technical experts don't just train—they tailor a playbook specifically for your machinery. Remember this: Real efficiency kicks in when your operators and equipment are finally in perfect sync.

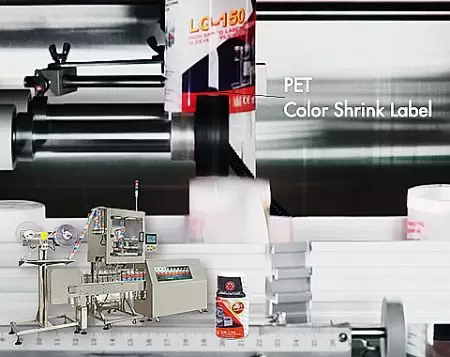

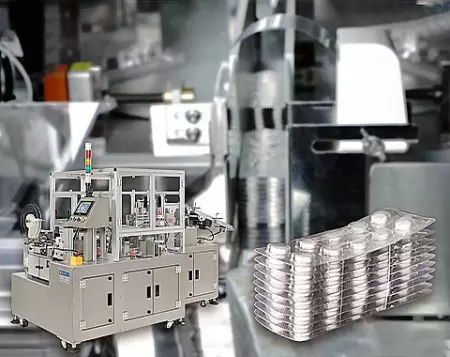

Recommendation of popular products, please see the product introducing pages for more details.

Packaging Machinery Training: Boosting Sustainability and Efficiency | Innovative Heat Shrink Machines and Sustainable Packaging Films

Based in Taiwan since 1962, Benison & Co., Ltd. has been a shrink packaging machines and plastic films manufacturer. Our main product packaging machines include, heat shrink packaging machines, automatic shrink wrap machines, heat tunnel machines, as well as plastic films and label printing services, which are CE certified and sold to over 50 countries.

60 years professional experience in packaging industry and total 400 workers locating in Taiwan's headquarters and three overseas branches of China, Philippines and Thailand. Also Benison has distributors around the world more than 50 countries to provide 24 hours service every day. As a company that manufactures the shrink wrapping machines as well as the shrink packaging materials, we can see to your total needs. Since 1962, We have developed both expertise and technology in our 60 years of experience, becoming a leader in the shrink packaging industry.

Benison has been offering customers high-quality heat shrink packaging and shrink wrap machines, both with advanced technology and 60 years of experience, Benison ensures each customer's demands are met.