Air Turbine Heat Tunnel

HS-130

The HS-130 chamber integrates 3 features of softening, shaping and shrinking to achieve volume reduction. Designed to meet the challenge of shrinking empty PET bottles, the HS-130 is also suitable for other types of bottles. To use 10 precision air knives inside the shrink furnace, heat is applied diagonally to immediately shrink labels using a wind-cutting design, achieving a visually appealing result without deformation or fogging issues. Even difficult-to-shrink empty bottles and glass bottles can achieve perfect results.

Say goodbye to the limitations of using electric furnaces to package PET and empty PET bottles; this solution replaces steam furnaces, significantly reducing concerns about factory humidity. The use of the HS-130 will effectively reduce factory floor space, making it ideal for factories with limited space. Unlike traditional shrink furnaces, our furnace body design allows for easy lifting, enabling quick resolution of unexpected situations. The softening furnace features a wind tunnel design, allowing for quick and precise adjustment of the air outlet without the need for tools.

Features

- Designed for factories with limited space, the integrated design of the softening furnace, temperature-controlled furnace, and shrink furnace results in a compact size, occupying minimal space.

- Provides excellent shrinkage effects for PET empty bottles and glass bottles, ensuring that labels remain undistorted without wrinkles or fogging.

- Ensures a stable packaging process with a heat-resistant PTFE conveyor belt and an upper pressure belt, preventing packaging items from tipping or skewing for more stable transportation.

- Convenient and swift troubleshooting with the lift-up design, allowing prompt handling of material jams or bottle overturns, effectively eliminating abnormalities.

- Suitable for various types of packaging, including cold bottles or glass bottles that are typically resistant to shrinkage.

- Compatible with materials such as PET, OPS, and PVC for versatile usage.

Specification

Machine Dimension:2888 (L) x 927 (W) x 1601 (H) (m/m)

Power:3Ø 220V

Tunnel Dimension:1600 x 160 x 260 (m/m)

Temp. in Tunnel:230 (°C)

Heater:13.5 (KW)

Tunnel Motor:400W x 2 / 60W x 1

Conveyor Motor:200W x 1

Max. Speed:70 Max BPM (For each additional unit, the packing speed increases roughly 50 bottles/min)

Applied Material:PVC / PET / OPS

Applications

- Empty bottles material: PP or PE bottle (Thermal expansion and contraction)

- Empty bottles material: CPET bottle (Thermal contraction)

- Empty bottles material: Aluminum can

- Movies

- Related Products

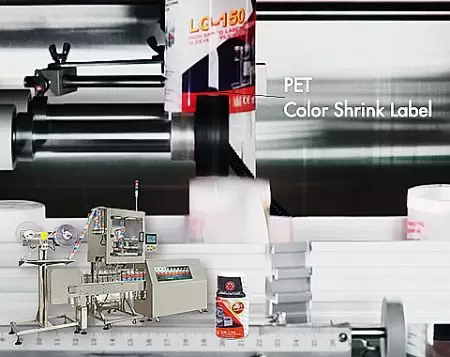

Auto Body Label/Tamper Evident Sleeve Applicator (Shrink Sleeve Machine), (250BPM)

LG-150(CE)

The LG-150 auto body label sleeve applicator is a high-speed automatic sleeve labeling machine, ideal for food, beverage, personal care, health, and chemical products.It handles up to 250 bottles per minute...

Details- Files Download

Recommendation of popular products, please see the product introducing pages for more details.

Air Turbine Heat Tunnel | Innovative Heat Shrink Machines and Sustainable Packaging Films

Established in 1962 and based in Taiwan, Benison & Co., Ltd. is a leading supplier of packaging solutions. We specialize in Air Turbine Heat Tunnel, shrink packaging, heat shrink films, tamper-evident bands, and automated packaging machines for the food, beverage, pharmaceutical, and industrial sectors. Our products include horizontal flow wrappers, auto label sleeve applicators, and over-wrapping machines, all designed to enhance production efficiency and reliability.

Our expertise spans both packaging machinery and film production, offering industry-leading technology and eco-friendly solutions. Advanced heat shrink packaging machines and automatic shrink wrap systems ensure high efficiency and reliability for various industrial applications. Sustainable shrink films provide excellent product protection and presentation. Focused on innovation and comprehensive customer service, we attract international buyers seeking top-quality and reliable packaging solutions, reinforcing our position as a global leader in the packaging industry.

Benison has been offering customers high-quality heat shrink packaging and shrink wrap machines, both with advanced technology and 60 years of experience, Benison ensures each customer's demands are met.