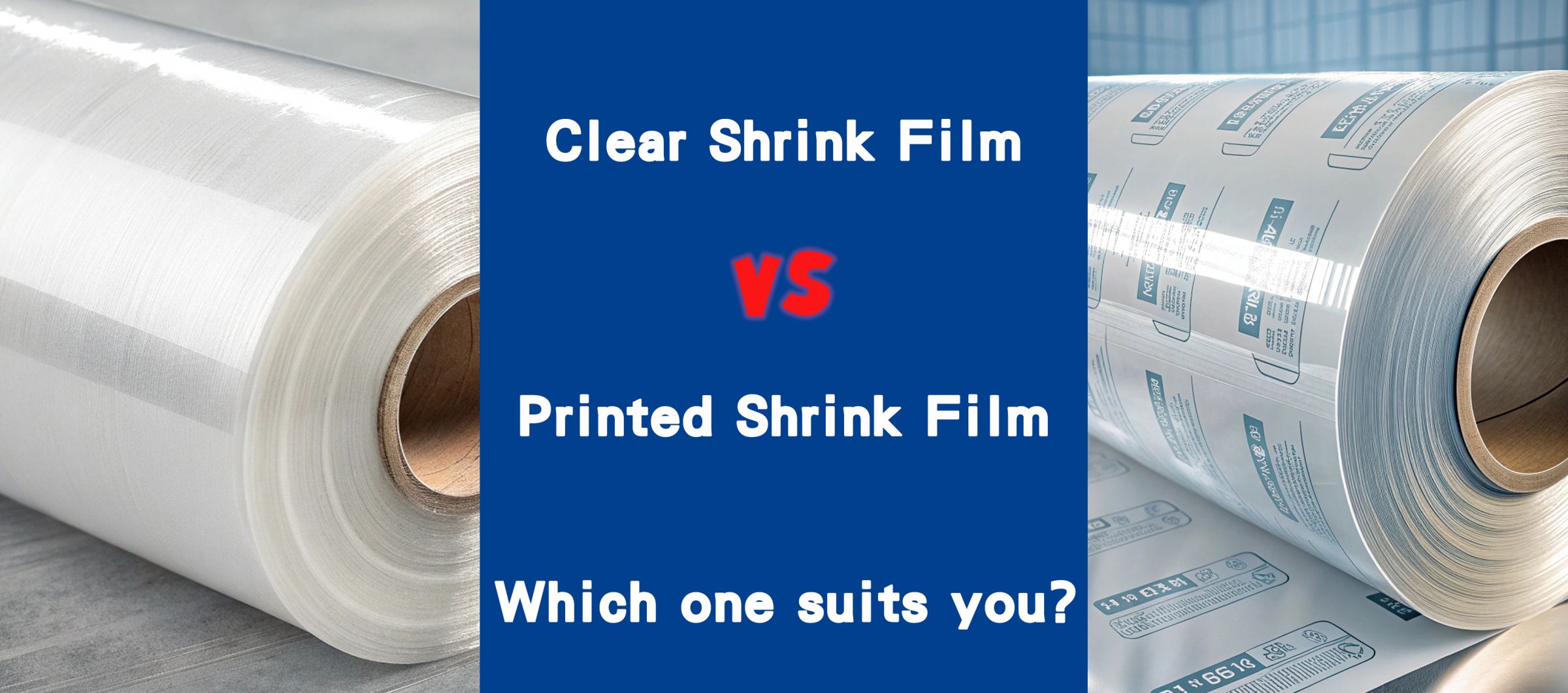

Clear Shrink Film VS. Printed Shrink Film: Which One Suits You?

People may think shrink film is just about appearance, but it' s tied to much more. The right choice can help with product stability, production efficiency, and the overall impression your brand gives on the shelf.

Clear and printed shrink films each have distinct benefits, fitting into completely different scenarios. Let' s look at this from a practical viewpoint to quickly break down the differences and help you find the solution that truly meets your product needs.

What Is Clear Shrink Film?

Clear film has been the go-to packaging choice across numerous industries. Once heat is applied, it tightens naturally, providing a clean, tight wrap around the product—giving it a more polished and premium finish.

Since it' s highly transparent, the product inside is clearly visible. That' s why you find it everywhere: protecting food, drinks, household goods, and even electronics on the shelf.

▍Common Materials

1.PVC Shrink Film:Lower cost, often used for general outer packaging of everyday items.

2.PE Shrink Film:Good stretchability and strong impact resistance, especially suitable for multi-pack or promotional packaging.

3.POF Shrink Film:Odorless and capable of withstanding low temperatures, making it suitable for various industries.

▍Advantages of Clear Shrink Film

1.Clear Product Display:High transparency allows the contents to be seen at a glance, increasing shelf appeal.

2.Good Protection and Sheen:It provides a tight wrap when heated, protecting against dust, scratches, and unwanted opening before purchase.

3.Highly Flexible Specifications:Width and thickness can be adjusted according to product size.

4.Ideal for Products That Already Have Inner Packaging Designs:Such as printed pouches or boxes.

What Is Printed Shrink Film?

The core difference here is that the film itself can carry graphics and information. Essentially, the outer layer of the shrink film becomes your brand's own canvas.

This is the choice for companies looking to boost brand visibility or ensure their product instantly catches the eye when stocked.

▍Material Characteristics

1.POF Printed Shrink Film:Shrinks evenly and offers excellent print quality.

2.PE Printed Shrink Film:Thicker and more durable—more suitable for multipacks, larger items, or heavy products.

▍Advantages of Printed Shrink Film

1.Full 360° Branding:Brand colors, nutrition details, product information, and barcodes can all be printed directly onto the film.

2.Pops on the Shelf:Ideal for new product launches or promotional campaigns with strong shelf appeal.

3.Replaces Sticker Labels: Eliminates issues with peeling or misaligned stickers, resulting in a more consistent appearance.

4.Fully Adaptable:Seasonal designs, promotions, or brand updates can be implemented with minimal effort.

How to Choose Clear or Printed Shrink Film?

1.Do you need stronger visual impact and brand recognition?

✔ Yes → Choose printed shrink film

2.Is your inner packaging already printed, and all you need is protection plus visibility?

✔ Yes → Choose clear shrink film

3.Do you want your packaging to show complete product information, especially for simple or plain-looking products?

✔ Yes → Choose printed shrink film

Which Shrink Film Is Best for Your Brand?

Clear shrink film works best when your priority is protection, safety, or when your product already has printed inner packaging; while printed shrink film is ideal when branding, information display, and shelf appeal are the main goals.

The most important thing is to look back at your product, target customers, brand strategy, and budget to determine the packaging option that truly matches your production needs.

Not Sure Who to Ask? Benison Is Here to Help.

Shrink films come in many types and applications. If you have a general idea but need final confirmation, we offer the following support:

◆ Material consultation:

Recommendations based on your product characteristics, storage conditions, and display needs.

◆ Custom printing & layout guidance:

Brand-aligned suggestions on print methods, colors, and layout to ensure consistency and strong recognition.

◆ Packaging efficiency & production integration:

Advice on the right shrink film size and specifications to improve productivity and cost effectiveness.

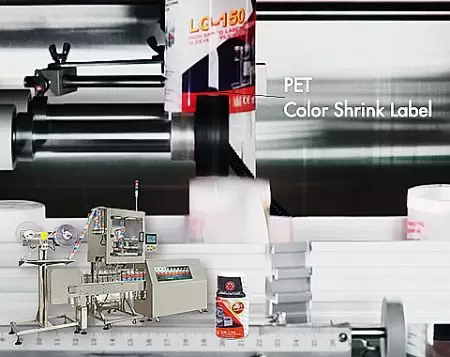

Recommendation of popular products, please see the product introducing pages for more details.

Clear Shrink Film VS. Printed Shrink Film: Which One Suits You? | Innovative Heat Shrink Machines and Sustainable Packaging Films

Based in Taiwan since 1962, Benison & Co., Ltd. has been a shrink packaging machines and plastic films manufacturer. Our main product packaging machines include, heat shrink packaging machines, automatic shrink wrap machines, heat tunnel machines, as well as plastic films and label printing services, which are CE certified and sold to over 50 countries.

60 years professional experience in packaging industry and total 400 workers locating in Taiwan's headquarters and three overseas branches of China, Philippines and Thailand. Also Benison has distributors around the world more than 50 countries to provide 24 hours service every day. As a company that manufactures the shrink wrapping machines as well as the shrink packaging materials, we can see to your total needs. Since 1962, We have developed both expertise and technology in our 60 years of experience, becoming a leader in the shrink packaging industry.

Benison has been offering customers high-quality heat shrink packaging and shrink wrap machines, both with advanced technology and 60 years of experience, Benison ensures each customer's demands are met.