Shrink Sleeve Applicator

ES-130 (CE), ES-200 (CE), GS-75, GS-100

Tamper Evident Band Shrink Tunnel

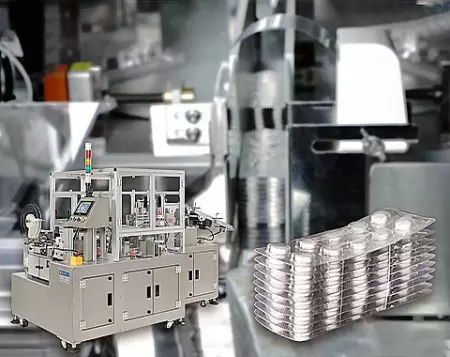

There are 4 type of heat tunnel to run any kind of shrink material; they are heat tunnel for wrapping purpose, steam tunnel, heat tunnel for shrink sleeve & mini-type heat tunnel. Those heat tunnels are designed to conveyor speed controllable, compact dimension, power saving, quick shrinking, quick movable & saving space to reduce packaging cost. It can also work in line to connect upstream & downstream equipment to be fully automatic.

Specification

● ES-130

Machine Dimension: 900 (L) x 800 (W) x 1480 (H) (m/m)

Power: 3Ø 220V

Tunnel Dimension: 900 x 130 x 190 (m/m)

Temp. in Tunnel: 200 (°C)

Heater: 9 (KW)

Tunnel Height Adjustment Device: Manual / Auto (Optional)

Applied Material: PVC / PET / OPS

● ES-200

Machine Dimension: 1500 (L) x 1000 (W) x 1900 (H) (m/m)

Power: 3Ø 220V

Tunnel Dimension: 1500 x 200 x 350 (m/m)

Temp. in Tunnel: 200 (°C)

Heater: 9 (KW)

Tunnel Height Adjustment Device: Manual / Auto (Optional)

Applied Material: PVC / PET / OPS

● GS-75

Machine Dimension: 580 (L) x 195 (W) x 475 (H) (m/m)

Power: 1Ø 220V

Tunnel Dimension: 580 x 75 x 100 (m/m)

Temp. in Tunnel: 250 (°C)

Heater: 5 (KW)

Tunnel Height Adjustment Device: Manual

Applied Material: PVC / PET / OPS

● GS-100

Machine Dimension: 580 (L) x 245 (W) x 515 (H) (m/m)

Power: 1Ø 220V

Tunnel Dimension: 580 x 100 x 150 (m/m)

Temp. in Tunnel: 250 (°C)

Heater: 5 (KW)

Tunnel Height Adjustment Device: Manual

Applied Material: PVC / PET / OPS

Applications

- GS heat tunnel is designed with direct heating air; it is for Tamper Evident Band specially.

- ES heat tunnel is designed with heating loop turbulence; it is for body label specially.

- Related Products

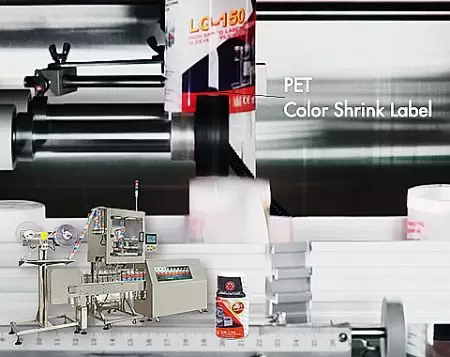

Auto Body Label/Tamper Evident Sleeve Applicator (Shrink Sleeve Machine), (250BPM)

LG-150(CE)

The LG-150 auto body label sleeve applicator is a high-speed automatic sleeve labeling machine, ideal for food, beverage, personal care, health, and chemical products.It handles up to 250 bottles per minute...

Details- Files Download

Recommendation of popular products, please see the product introducing pages for more details.

Shrink Sleeve Applicator | Innovative Heat Shrink Machines and Sustainable Packaging Films

Established in 1962 and based in Taiwan, Benison & Co., Ltd. is a leading supplier of packaging solutions. We specialize in Shrink Sleeve Applicator, shrink packaging, heat shrink films, tamper-evident bands, and automated packaging machines for the food, beverage, pharmaceutical, and industrial sectors. Our products include horizontal flow wrappers, auto label sleeve applicators, and over-wrapping machines, all designed to enhance production efficiency and reliability.

Our expertise spans both packaging machinery and film production, offering industry-leading technology and eco-friendly solutions. Advanced heat shrink packaging machines and automatic shrink wrap systems ensure high efficiency and reliability for various industrial applications. Sustainable shrink films provide excellent product protection and presentation. Focused on innovation and comprehensive customer service, we attract international buyers seeking top-quality and reliable packaging solutions, reinforcing our position as a global leader in the packaging industry.

Benison has been offering customers high-quality heat shrink packaging and shrink wrap machines, both with advanced technology and 60 years of experience, Benison ensures each customer's demands are met.